Equipment used in explosive (Ex) atmospheres has a much higher capital cost than the same equipment used elsewhere. Consequently, repairing it is often more cost-effective than replacing it. This is why IECEx set up the IECEx certified facilities scheme, which assesses and certifies that organizations that provide services that deal with the installation, inspection or repair and overhaul of Ex equipment, such as Ex repair workshops, offer such services to the Ex industry, and do so according to the strict requirements of IEC International Standards.

|

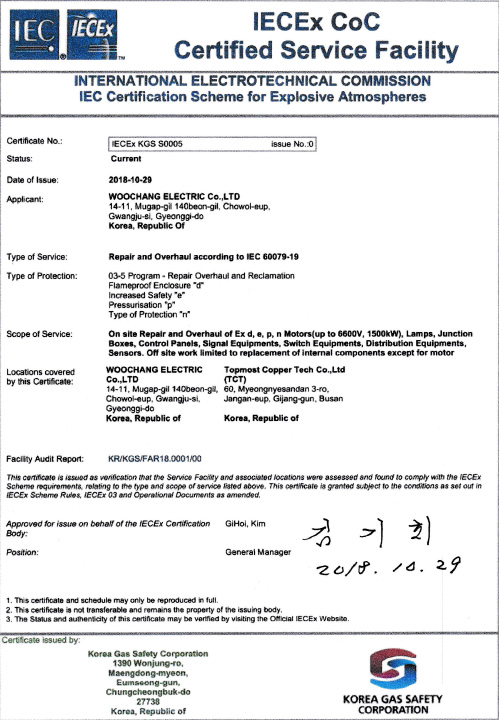

The WOOCHANG has certified IECEx Service Facility of Repair by IECEx and KGS in 2018, even the first in Koea. Therefore the WOOCHANG has give the service repaired Ex equipment installed in HAC complied with IEC 60079-19 and has received annually the QMS Audit by KGS with IEC standard Series. |

|---|

|

|---|

| The WOOCHANG has certified IECEx Service Facility of Repair by IECEx and KGS in 2018, even the first in Koea. Therefore the WOOCHANG has give the service repaired Ex equipment installed in HAC complied with IEC 60079-19 and has received annually the QMS Audit by KGS with IEC standard Series. |

The key element of the IECEx certified service facilities scheme is initial and periodic audits by an IECEx certification body that has been accepted and authorized to issue IECEx certificates to service facilities. The purpose of these management system and technical audits is to ensure that services offered and delivered under the banner of IECEx certification always continue to comply with IECEx requirements and those of the relevant IEC International Standards.

|

This means that the WOOCHANG certified by IECEx and KGS recognizes the repair work implemented in accordance with IEC 60079-19, KGS GC 104 and KOSHA GUIDE E-177-2019. |

|---|

|

|---|

| This means that the WOOCHANG certified by IECEx and KGS recognizes the repair work implemented in accordance with IEC 60079-19, KGS GC 104 and KOSHA GUIDE E-177-2019. |

| 롯데BP화학㈜ | 고압모터 수리보수에 대한 방폭기기 성능평가 성적서 - 1건 발행 (2019년, 국내 최초 적용) |

|---|---|

| 롯데이네오스화학㈜ | 고압모터 수리보수에 대한 방폭기기 성능평가 성적서 - 8건 발행 (2021년) |

| SK지오센트릭㈜ | 저압모터 수리보수에 대한 방폭기기 성능평가 성적서 - 3건 발행 (2022년) |

Step 01

MOU with motor repair companyStep 02

Site surveyStep 03

The inspection, examination and test before dismentledStep 04

The inspection, examination and test after dismentled in detailsStep 05

Repairing workStep 06

The final test after reassembledStep 07

Marking of repairStep 08

The installation on siteStep 09

The submition of the final report(w/the Performace data)| ISO 9001 ISO 80079-34 |

IEC 60079-19 IEC 60034-23 IEC 03-05 |

IECEx OD 314-5 IECEx OD-504 IECEx OD 315-5 IECEx OD-301 |

KOSHA GUIDE E-177-2019 KGS 104 |

특정 분야인 모터에 대한 전문성을 향상시키기 위하여 모터 수리업체와 업무협약 후 수리보수 진행

| The role of Moter Repair Company | The WOOCHANG certified by IECEx and KGS |

|---|---|

| The Work of the motor repair | the Project management with the performance data |

Fax 031.769.0138